Product CenterMakersoon

Related Products

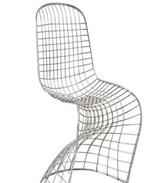

Imitation plating powder

The imitation electroplating powder coating is prepared by using epoxy resin and polyester resin as the main raw materials, and has their own unique properties, so that the produced coating film has excellent leveling, decorative, metallic effect and luster. degree. Mainly used for metal furniture, metal coatings and other industries require surface coating.

next

Product Introduction

The imitation electroplating powder coating is prepared by using epoxy resin and polyester resin as the main raw materials, and has their own unique properties, so that the produced coating film has excellent leveling, decorative, metallic effect and luster. degree. Mainly used for metal furniture, metal coatings and other industries require surface coating.

Specifications

Powder covering is a dry complete finish procedure that has gotten very mainstream since its presentation in North America over during the 1960s. Speaking to over 15% of the all-out modern completing business sector, the powder is utilized on a wide cluster of items. An ever-increasing number of organizations determine powder coatings for an excellent, sturdy get done with, taking into consideration expanded creation, improved efficiency, and rearranged ecological consistency. Utilized as utilitarian (defensive) and embellishing completes, keep the surface clean powder coatings are accessible in a practically boundless scope of hues and surfaces, and innovative head ways have brought about incredible execution properties.

Powder coatings depend on polymer sap frameworks, joined with curatives, shades, leveling specialists, stream modifiers, and different added substances. These fixings are dissolve blended, cooled, and ground into a uniform powder like heating flour. A procedure called electrostatic shower statement (ESD) is commonly used to accomplish and spray the use of the powder covering to a metal substrate, when metal part finishing process. This application technique utilizes a splash firearm, which applies an electrostatic charge to the powder particles, which are then pulled in to the grounded part. After the utilization of the powder covering, the parts enter a restoring stove where, with the expansion of warmth, the covering artificially responds to create long atomic chains, bringing about high cross-connect thickness. These atomic chains are extremely impervious to breakdown. This kind of use is the most well-known strategy for applying powders. Coating powder can likewise be applied to non-metallic substrates, for example, plastics and medium thickness fiberboard (MDF).

In the early days of the development of Powder Coatings in China, due to lack of information, the selection of pigments and color matching was inevitably affected by the experience of solvent-based coatings, inks and plastics industries. With the rapid development of the industry and the enrichment of relevant knowledge and information, powder coatings are much more targeted and the standards are higher and higher when selecting pigments. If you do not want to understand the chemical composition and related properties of various pigments, you will face hundreds Thousands of pigment models will be at a loss, resulting in high color matching costs or failure to meet usage requirements. We have High Temperature Resistant Powder Coatings on sale, welcome to consult.

Color is the most basic property of pigments. People may use this to classify pigments into red, yellow, and blue. The color of the pigment is mainly determined by the chemical structure and crystal form, and the particle size has an effect on the hue. When it comes to color, pay attention to chroma or saturation, which is commonly referred to as vividness. Saturation is one of the attributes of color, which indicates the degree of deviation of the color from the same gray. It depends on the pigment's selectivity to light wave reflection. The higher the selectivity, the higher the great chroma. Various monochromatic lights of visible light have the highest chroma. In actual color matching, pigments with higher chroma can be used to match lower chroma colors, and vice versa. Some boards made with organic pigments cannot be made with inorganic pigments no matter how the amount is increased, which is due to the limitation of the lower saturation of inorganic pigments. For some particularly bright liquid or paint swatches, powder coatings cannot be called out, because the pigment concentration in powder coatings is low, and at the same time, the high curing temperature excludes many heat-resistant bright pigments.

The tinting strength, also called tinting strength, is the ability of a pigment to make a colored object have a color. It mainly depends on the chemical structure, and is also related to factors such as crystal form and particle size. Our coatings mainly supply to industrial equipment, everything’s surface to make their surface more smooth, artificial and durability.

Heat resistance is mainly related to chemical structure and crystal form pieces, but also to particle size, powder coated surface treatment and other factors. In addition, the heat resistance of many pigments is reduced after dilution.

Light resistance reflects the degree of pigment darkening and fading under light. It is divided into 1 to 8 grades from severe to slight, and 8 grades indicate the best light resistance. Weather resistance more comprehensively reflects the fastness of pigments under natural outdoor conditions, from the worst to the best divided into 1 to 5 grades. The light resistance and weather resistance of pigments mainly depend on the chemical structure, and are also related to crystal form, particle size, and surface durable treatment. Many pigments have reduced light resistance and weather resistance after dilution.

As a Powder Coatings Manufacturer, we can provide you completed services and quality products with low price, we also can offer many custom colors as you need, even a small or great demand! We are warmly welcome you to see and try our new products, won’t disappoint you!